.

.

.

.

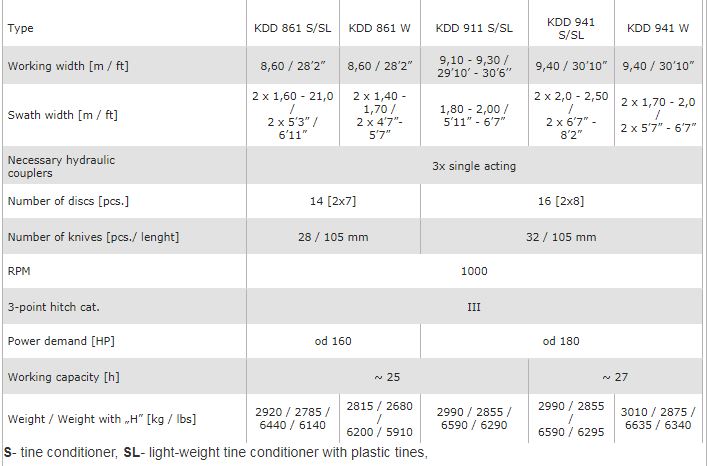

Economy of mowing together with high efficiency is the best description of GigaCUT sets. They have been designed to work on large farms in the toughest conditions.

GigaCUT combination consists of double-sided mower KDD 861 S/W or 941 S/W and front mower KDF 300 S/W or KDF 340 S/W + belt conveyors.

Owing to tine or roller conditioner, use of tedder and rake is no longer a necessity, and besides that is an alternative to self-propelled mowers.

.

.

.

.

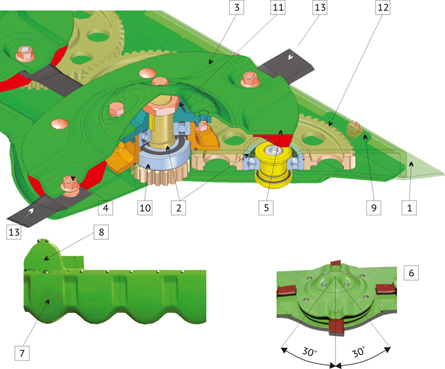

Safety breakaway devices

Safety breakaway devices

GigaCUT sets are equipped with two safety breakaway devices (similar to MegaCUT sets). They protect mower against hitting into small obstacles. In the event of hitting an immovable obstacle the cutterbar folds back about 30 degrees and at the same time rises about 70 cm. Afterwards, the cutterbar automatically comes back to its working position.

.

.

.

.

.

.

.

Mechanical lock

.

.

.

.

.

.

.

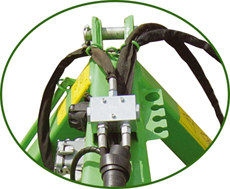

Belt conveyor regulation valve

.

.

.

.

.

.

.

Flow divider

.

.

.

.

Approach sensor

Approach sensor

Approach sensor similar to the one in MegaCUT. This option is very important when taking turns over swaths. An operator does not have to control lifting height of mowers and the risk of PTO shaft damage is eliminated.

.

.

.

.

.

.

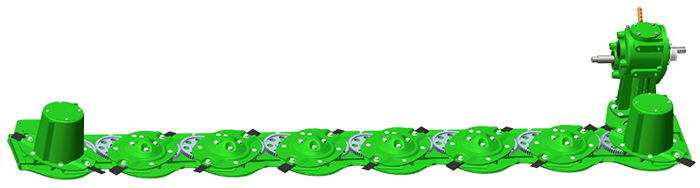

GigaCUT combination is equipped alternatively with tine or roller conditioner. Additionally, belt conveyors can be mounted, owing to which raking is eliminated and the silage wagon or forage harvester needs three times less runs to pick up the swath.

Equipment and advantages of GigaCUT sets:

• Central suspension

• Linkage frame adjusted to II and III cat.

• Lowered rotation point

• Hardened suspension frame

• 4 support springs

• New integrated cutterbar gearboxes

• Interchangeable tine and roller conditioner

• Adjustable tine conditioner’s guard

• Mechanical lock during transport

• Approach sensor

• Own cooling unit

• Flow divider similar to MegaCUT

.

PTO shaft with friction clutch

PTO shaft with friction clutch

Drive from central gearbox to cutterbars is transmitted through PTO shafts with overrunning friction clutch, which protect the cutterbars against damage.

.

.

.

.

.

.

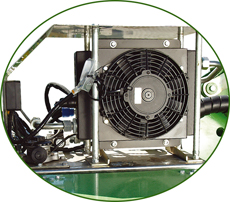

Hydraulic unit

The mower has its own hydraulic unit: oil pump, oil container, oil cooler with a fan and valve regulating working speed of belt conveyors.

.

.

.

.

.

.

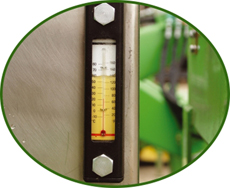

Level and oil temperature indicator

There is an integrated level and oil temperature indicator placed on oil container.

.

.

.

.

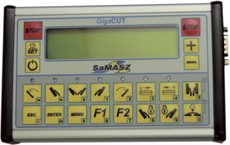

Electric steering panel

Electric steering panel

Electric steering panel makes it more comfortable to manouver mower’s units: switching on the conveyors, lock when taking turns over swaths, option which mower (left or right) to steer.

.

.

.

.

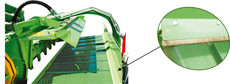

Belt conveyor’s cleaning mechanism

Belt conveyor’s cleaning mechanism

The conveyor is equipped with roller’s cleaning mechanism, owing to which the dirt can be removed without the necessity to take off the belt. In order to eliminate the dirt from coming underneath the belt there are new types of brushes.

.

.

.

.

.

.

.

Hard main gearbox -100 kV

.

.

.

.

.

.

Belt conveyors

Belt conveyors

Belt conveyors in GigaCUT sets are driven by their own hydraulic unit and consist of hydraulic pump, oil cooler and two hydraulic engines. Switching on and off the conveyors (independent) is done by means of an electric panel mounted in the tractor’s cabin.

.

.

.

Belt conveyor’s design

Belt conveyor’s design

1. Integrated conveyor’s frame

2. Heightened conditioner’s guard enable better material throw to the belt.

.

.

.

.

Manufacturer’s advice

Belts’ speed – regulated manually as standard from 0 – max. Maximum swath width 2,8 m may be reached when low and middle high grass prevails. When the high and stiff grass prevail the speed of the conveyors has to be increased due to blocking of the belts by the material. This automatically narrows down the swath. There is a possibility to move the conveyors left and right along the mowers +- 200 mm. However, an operation with the conveyors moved to an extreme point may cause unbalancing of the set. In that case, if there is a necessity to reach 3,5 m swath SaMASZ can manufacture shorter conveyors.

.

.

.

.

.

Transport position

In this position the wings of the mower are uplifted and permitted transport width 3,0 m is not exceeded.

.

.

.

.

.

.

Adjustment of cutting units

Overlapping between front mower and rear mowers is set on 375 mm.

In GigaCuT set collected swaths form either one or three windrows.

.

.

.

PERFECT CUT

Based on the experience of our customers in Poland and in Western Europe we have introduced to our production a new model of cutterbar: Perfect CUT. Precise cut, high durability of components, protection against sudden disc stop in case of coming into an obstacle, quick and easy disc module replacement owing to modernized upper disc hub are the main advantages of Perfect CUT cutterbars. New cutterbar is mounted in every SaMASZ disc mower apart from KDL series based on Comer cutterbar.

.

.

Main advantages of PerfectCUT cutterbar:

Main advantages of PerfectCUT cutterbar:1. Smooth regulation of cutting height from 4 to 7 cm.- sliding skids from 5 to 9 cm

2. 6307 2RSN bearings in bevel gears and 6307 2RS in disc modules are the most durable and unprecedented among our european competion.

3. Specially hardened discs and sliding skids made of Boron steel, protected against mud and dirt by means of the blades.

4. Easily replaceable knife holder pins.

5. Hardened knife holder made of Boron steel, especially designed in order to eliminate stucking of the knives under the disc.

6. Innovative system of quick knife replacement. The knife can be changed only when the disc is adjusted sheer to the cutterbar (+ – 30 degrees). The system decreases the probability of knife loss almost to absolute minimum in case of hitting into stone.

7. Modernized, hardened sliding skids made of Boron steel protect the whole surface of cutterbar on the bottom. Quick and easy replacement of the skids (only two bolts to unscrew).

8. Additional steel skid protecting cutterbar’s drive.

9. Hardened cutterbar made of steel.

10. Protection against stones in standard equipment.

11. Quick and easy replacement of disc module thanks to modernized upper hub.

12. Bevel gears with 25 mm tightness.

13. High quality knives comply with strict safety rules. SaMASZ logo engraved on the knife is a guarantee of its quality.

.

.

Protection against stones in standard equipment

Protection against stones in standard equipment

Specially designed disc module protects the cutterbar with bevel gears in case of very strong, extreme hit of the disc e.g in a stone. The force of the hit cuts off only the key. Then, only the module needs to be replaced without the necessity of expensive cutterbar repair. The replacement of the module takes only a while and can be done on the field. Owing to that solution the time crucial during forage pick-up is spared. Modernized upper disc hub enables quick module replacement. Special cavities for bolts make it very easy to disssemble the module without the necessity of unscrewing upper hub. The drive of the discs is transmitted by means of bevel gears with high diameter, which increases the resistance of the disc in case of hitting into an immovable obstacle..

.

.

Comparison of bevel gears

Comparison of bevel gears

Our mowers are equipped with Perfect CUT cutterbars based on bevel gears transmitting higher strength.

.

.

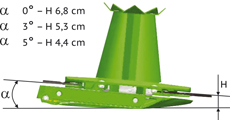

Perfect quality of cut with Perfect CUT cutterbar

Perfect quality of cut with Perfect CUT cutterbar

New Perfect Cut cutterbars have high quality of cutting even with very low grass during 3, 4 and further cuts. During 1 and 2 cut when high grass prevails it is recommended to cut with height between 53 mm and 68 mm. Depending on the angle of cutterbar’s inclination there are the following cutting heights.

.

.

Perfectly profiled design

Perfectly profiled design

Rounded shapes of cutterbar’s bottom surpass the designs of other manufacturers. Streamline shape facilitates operation on more earthen and stony paddocks. No sharp edges on the whole cutterbar, smooth surfaces of sliding skids give protection to the turf.

.

.

Quick knife replacement by means of special key.

Quick knife replacement by means of special key.

.